How to effectively manage multiple inventories and their procurement

Seamless inventory management and procurement are highly significant in determining your company’s financial health. Consequently, to extract the most out of it, businesses need to understand these in the light of effective management. As brands grow out from smaller warehouses and into more extensive facilities, the need to manage inventory increases efficiently.

An effective inventory system is a cornerstone for strategic eCommerce and online retail management. An optimized inventory solution that provides real-time data conditions can help achieve many benefits for your organization. These robust systems also protect from issues like refunds and attract more repetitive buyers.

What’s Multiple Inventories + Procurement?

A systematic approach toward sourcing, warehousing, and selling raw materials and finished goods is called inventory management or procurement. Your business practices this to ensure that you have enough stock in hand whenever a shortage occurs, as the more stocked you are, the smooth is the process of manufacturing and selling your products.

Today, we live in a consumer-centric era where small-to-medium startups compete with global conglomerates. Standing shoulder to shoulder with these IT giants requires small-scale businesses to be well equipped in the basic types of inventories.

Inventories and procurement can break down the types into five main categories:

Raw material

The base materials used in the manufacturing of finished products are called raw materials. Industries can purchase them via a supplier or through a company that works in procuring these from scratch.

Processing inventory

Retailers that manufacture their products belong to the work-in-progress inventory. These involve human labor that puts together raw materials to form unfinished products that are not yet ready for sale.

Final/finished products

Completed goods that are ready for display in the market are finished products. They can be moved up the supply chain, ready to be sold. Retailers mostly purchase finished products from suppliers or get them custom-made via a third party. These goods are either consumed or discarded.

Maintenance, repair, and operations (MRO)

Supplies used in the manufacturing of a product but are not a part of it are called MRO goods. They include items like cleaning equipment, machinery, or batteries.

Packing

This stage includes packing the finished product before shifting it to the market. It has things like bubble wrap and padding to protect the goods from harm while in transit.

How to build Multiple Inventories + Procurement?

Jestor can help you solve all queries related to multiple inventories and their procurement with a few clicks on your screen. Installing the template would suffice and cater to all your inventory management requirements.

Step one

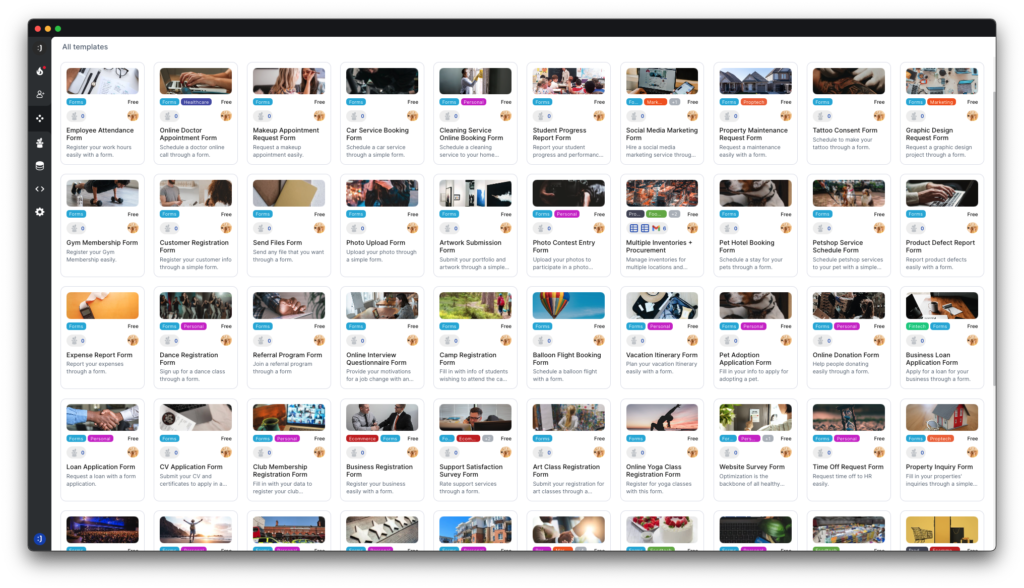

As soon as you create your account, you’ll be on the Templates page.

Step two

In the search templates bar, type “Procurement.” Select the first thumbnail that appears.

Step three

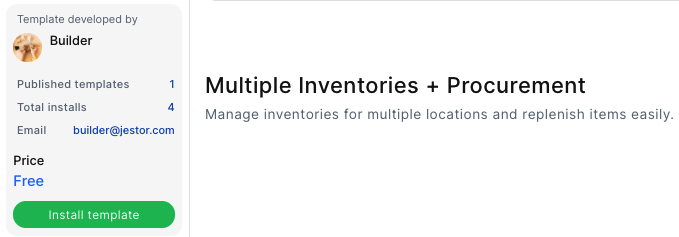

To use the template, simply click on “install template” on the bottom-left side of the screen.

Step four

As soon as the template is installed, you’ll receive a notification and the tables and apps will appear on your menu

Once you have filled in the required fields according to your requirements, click on Submit. Jestor will store the information in the database, and you can edit it whenever an update is needed.

Pros and Cons of Multiple Inventories + Procurement

The most challenging component of inventory procurement is determining the optimal quantity of goods to hold in stock. Sometimes, this can positively impact your company – especially when you need to make subsequent deliveries. Having an excess of goods is effective only for companies that move their inventory regularly and quickly.

Let’s delve into some of the advantages and disadvantages of holding goods in excess to determine an adequate solution for your business.

Pros

- Quick order delivery

When you have multiple stocks in your inventory, you can ensure meeting customer requests within the required time frame. Faster delivery of customer purchases will positively impact your business. - Decreased storage risk

Along with faster order fulfillment, multiple stocks also eradicate the risk of having a shortage of items. It also facilitates the application of Just-In-Time (JIT) production strategies. - Discount deals

Your business can also benefit from supplier discount deals if you make purchases in bulk. These discounted deals help reduce costs and allow you to make a more significant profit on your sales.

Cons

- Increased expenditure

One of the biggest challenges faced is the cost associated with storage. The more items you have, the more space you need to store them. These costs include storage costs, inventory control, or audits. - Out-dated inventory

Multiple inventories also have the chance to become obsolete before you sell them all. If you do not encourage continuous innovation in your products, they can lose their charm once the craze is over.

How much Important is Inventory Management for your Business

A goods-based business needs an optimized inventory solution as it adds value to your operational efficiency and its longevity. If you are not using a smart approach to enterprise resource planning ( ERP), you’ll need to get on board with an army of challenges shortly.

The following points highlight the significance of inventory management:

- Reduction in the overall costs/expenditure

- Optimized fulfillments of customer order placements

- A satisfactory customer service

- Prevention from theft, loss of goods, spoilage, and unplanned returns

If you look at inventory management from a broader perspective, you’ll realize that it offers a lot more to your company – valuable insights into your financial standing, end-user behavior/preferences, future trends, or business opportunities.

Conclusion

For the success of your brand and business, inventory management is a must-have skill. A state-of-the-art design solution provides robust inventory management support that has increased overall efficiency and customer satisfaction levels. When you plan a supply chain strategy, you must also consider the advantages and disadvantages of multiple inventory management to help balance out the costs and resources.

Feel free to try out more templates at Jestor that can help improve the overall management of your business in a variety of domains.